Calculate Your Sprocket's Final Drive Ratio For Top Speed

Are you gearing up? Adding teeth? Or is your motorcycle or ATV simply stuck with the stock sprockets you've been given? Chances are, if you haven't adjusted your drive ratio by changing your sprockets, you can probably do better - and for less money than you think.

When you bought your motorcycle or ATV, it was full of compromise. It had to be. It didn't really know you, or your abilities, or your physical size, or where you ride. This "compromise" is most evident in the stock tires and wheels, as well as the chain and sprockets.

All of these - except maybe wheels - are "wear" items that eventually need to be replaced. Tires may be the most evident of these. But did you know that a simple sprocket swap could do even more for your bike? We're not just talking about when the original wears out. So we'll explain gearing and sprocket sizes, as well as applications, and we'll show you some of our favorite sprocket products.

Sprocket Ratio Calculations

This may sound like you're prepping your gear for a trip to the trails, but we're talking about something else. You "gear up" or "gear down" by changing sprockets, front or rear, to different sizes. Because you can change either front or rear sprockets, it's best to begin by determining their relationship.

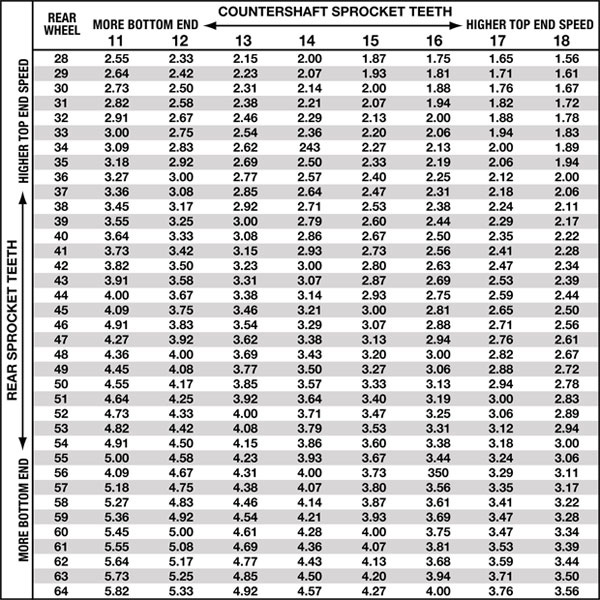

Sprockets, or "chainwheels" more literally, are measured by their number of teeth. To determine the final drive ratio, divide the rear sprocket size, say 49 teeth, by the front or countershaft sprocket size, say 13 teeth (like a new Yamaha YZ250F). In this case, the Final Drive Ratio is 3.77 - the front sprocket revolves 3.77 times to make one complete revolution of the rear sprocket.

The final drive ratio on a motocross bike will likely stay close to 4.0. For street bike guys, there's a much bigger spread of ratios depending on sportbike or standard. For sport ATV riders, the stock final drive ratio will generally be lower, around 3.0 or less.

Back to that YZ250F. If you replace its 49T rear chainwheel with a 52T - and that's a big change - your final drive ratio is now 4.00 (52 divided by 13). You just "geared down." That may sound backwards, but the relation is always to the front or countershaft sprocket, and in that relationship, you geared down. This number is most important when you're changing gearing. It's easy and beneficial to be scientific about this. And when you want to make a change, you should be scientific. Make one small change at a time, document it and test it before considering further changes.

What is Gearing Up?

This may sound like you're prepping your gear for a trip to the trails, but we're talking about something else. You "gear up" or "gear down" by changing sprockets, front or rear, to different sizes. Because you can change either front or rear sprockets, it's best to begin by determining their relationship.

Why Change Your Motorcycle's Drive Ratio?

Want the short answer? Gearing down by installing a larger rear sprocket (like with our YZ example) increases the final drive ratio and reduces top speed, but can increase acceleration.

Gearing up, like with a smaller rear sprocket, decreases the final drive ratio and adds more top speed to your motorcycle or ATV.

Short answers never tell the whole story, of course. Setting the gearing for any motorcycle or ATV presents a trade-off between low-end power delivery and top-end speed. If you like a nice blend of the two and are happy with the power delivery of your vehicle in stock form, then leave the drive ratio alone. Just keep an eye on your sprockets (and chain) for wear.

If you want better top-speed or stronger acceleration - and it's not easy to get both - then gear up or gear down, and you can do so for $100 or less (sometimes way less).

If you're a beginning rider, you might consider gearing down. Low-end power delivery and more effective acceleration will serve you better than top speed. Expert riders may already know how to get the best low-end delivery, and might want to gear up a vehicle for improved top-end power. But let's look at specific applications to give a better answer.

ATV Sprocket Ratio

A technical track or trail loop with deep soil, sand or elevation changes will require Gearing Down. This will give you strong acceleration out of corners, and let your bike or ATV better use power to pull through the soil or up hills. You may have to shift more often, but you'll get the strong pull you needed.

If your favorite track or trail is hard-packed with big sweeping turns, then you may want to Gear Up and make the most of your machine's top-end power delivery. You will lose access to some low-end power, and may have to use more clutch for low-rpm control. In exchange, you'll get more of what you want at higher rpm in improved top speed. You can also gear up if you've made other modifications to your bike or ATV that improve acceleration.

Ride a Suzuki LT-R450 and want even better low-end power? Gear down. Switch that stock 36T rear sprocket for a 37T or 38T.

Ride a Kawasaki KX450F and want more top-end? Gear up. Switch that stock 50T sprocket for a 49T.

Street Motorcycles Sprocket Ratio

If you ride a sportbike on certain technical roads or race tracks, perhaps, you can gear down for best acceleration and low-end power delivery.

For street riders specifically, changing gearing can help you tune your bike to a desired cruising rpm. For example, if your bike rolls down the freeway at 6000 rpm at 65 mph, you could gear up to lower that cruising rpm, reducing vibration and improving fuel mileage.

Changing gearing on street bikes can be more complicated than with a motocross bike or ATV. If you change the front sprocket, your street bike's speedometer will very likely read incorrectly. You'll need to correct that. Also, changing sprockets on a track-riding sportbike can change the effective wheelbase of the bike enough to affect handling. Those effects are not as pronounced on a dirt bike or quad.

Sprocket Construction

Most sprockets are made from either steel or aluminum, or maybe even a mix of the two. Steel sprockets are generally less expensive, and better for longevity. Countershaft sprockets are often made of steel; they need to be durable and their small-size means weight is usually not an issue. The best steel sprockets use hardened and heat-treated steel.

Sprockets made of aluminum are significantly lighter, but have a shorter life span, and are more expensive than steel. For race bikes or ATVs, the weight savings can be huge, often a couple pounds. For added durability, aluminum can be anodized, but sprocket life span is not an issue for most racers.

Our Favorite Sprockets

JT Sprockets makes more sprockets - about 18 million annually - than any other manufacturer in the world.

In recent years, JT has begun using more durable C49 steel with a high-carbon content. For competition-quality sprockets, JT uses 7075 T6 aluminum. Its high strength-to-density ratio makes it ideal for racing applications. JT's countershaft sprockets are made of full heat-treated chromoly SCM415 steel. Many other manufacturers simply "surface harden" their countershaft sprockets.

JT has fitment for more than 95 percent of bikes and ATVs in use today.

You may think of Renthal primarily as a handlebar maker, but the company's chainwheels are chosen by hundreds of champion racers. Renthal makes sprockets for off-road and road applications, mainly from 7075 T6 aluminum. The company's unique Twinring off-road chainwheel features steel teeth on an aluminum inner ring for a product that is lightweight and durable.

All of Renthal's chainwheels are CNC machined for precision, and to provide a combination of lightweight and strength. Renthal front chainwheels are made from nickel-chrome-molybdenum alloy steel, and are case hardened.

How Sprockets Affect Chains

When changing your sprockets due to wear, you will also need to replace your chain. The chain and sprocket relationship is best when the two wear together. Mixing an old chain with a new sprocket - or vice versa - will shorten the life of either. Not a good idea. And if you make a big change in sprocket size, you may need a shorter or longer chain.

Changing one tooth on the countershaft sprocket has a more significant impact on the gearing than changing one tooth on the rear sprocket. Plus, countershaft sprockets cost less. But, it's most often best to make changes with the rear sprocket. You get more fine adjustments, and that's generally desired.

Avoid using a smaller-than-stock front sprocket. On a smaller sprocket, the drive chain must turn a tighter radius, which increases friction and decreases the life expectancy of the chain.

Browse ChapMoto.com for a complete selection of motorcycle sprockets.